September 19, 2023

An environmentally friendly alternative to fluorocarbons for inhibiting protrusion of coatings in fabrics

Brecht Demedts (Centexbel), Yasmine Van Thuyne (Alsico High Tech)

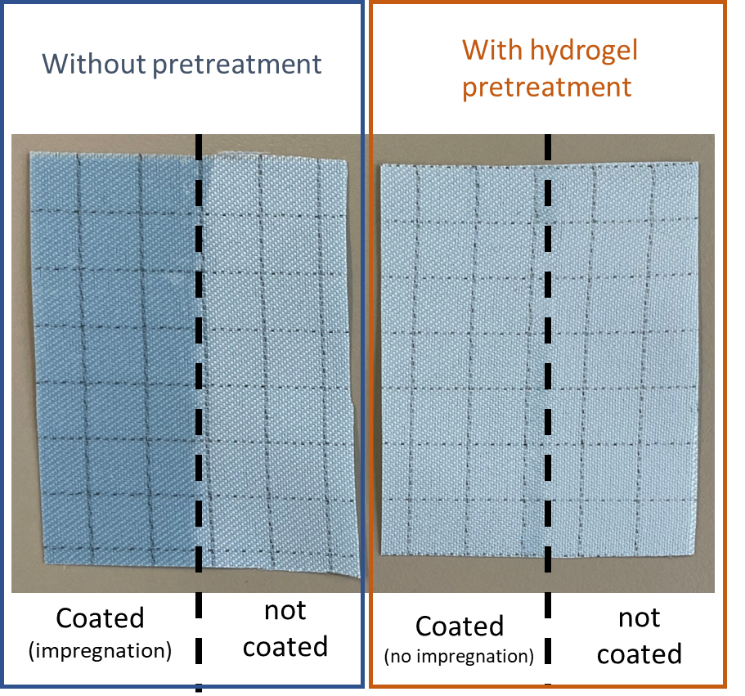

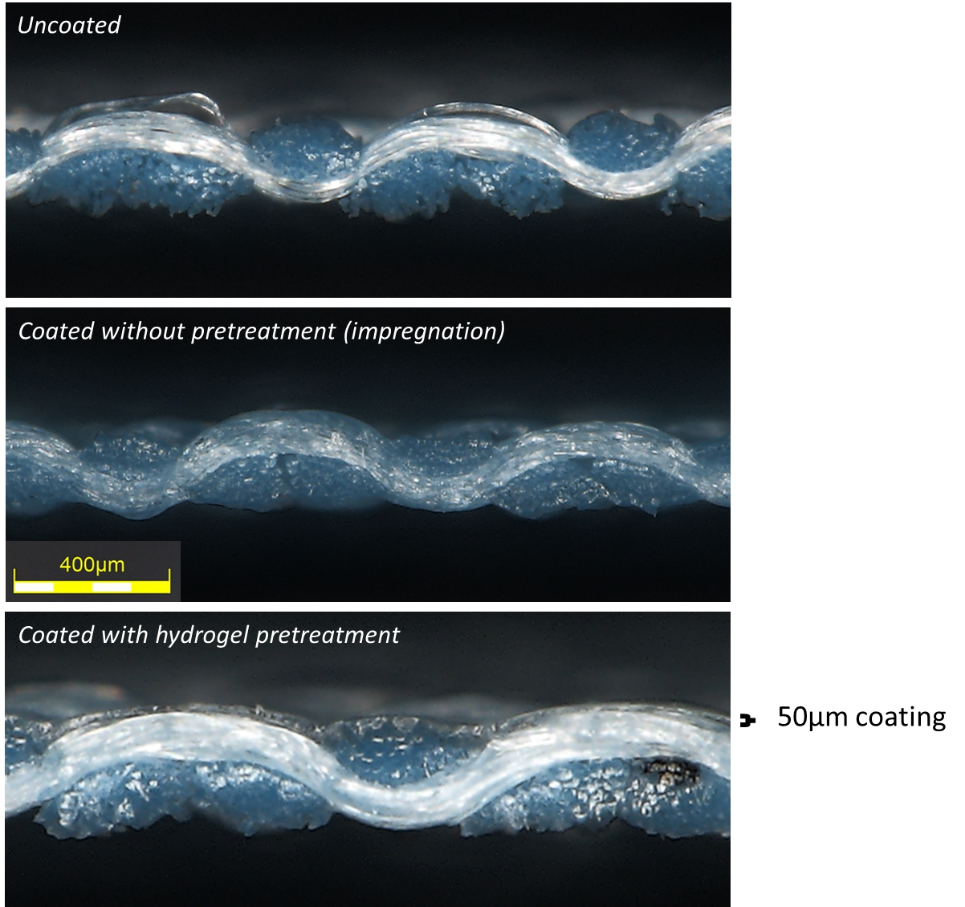

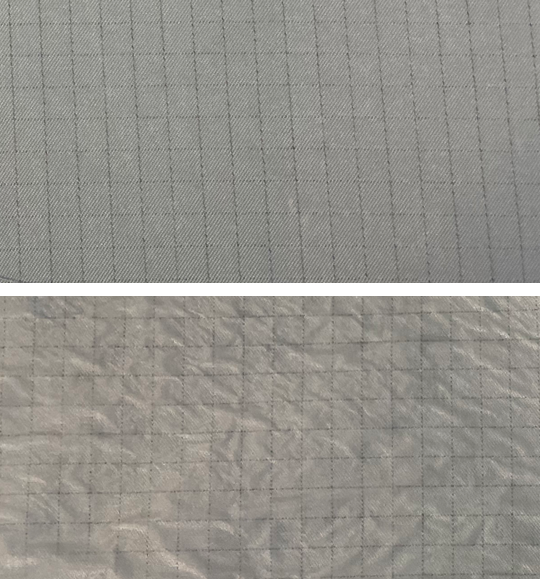

Fabrics are fibrous substrates with a very larger surface area in result of which they absorb liquids very well. The large absorption of fluids can happen both by capillary effects and through molecular swelling (e.g., water uptake by interacting through hydrogen bonds with cellulose). While this is a big advantage for comfort, it is an unwanted feature when adding coatings to textiles because the coating pastes soak into the fabric, rendering uncomfortable feel and touch. In order to circumvent this, typically fluorinated pretreatments are given to the textiles in order for coatings to remain on the surface of the fabric. The figure below presents a simple method based on hydrogels that RELIANCE partner Centexbel uses to prevent protrusion of coating pastes in a fabric.

An urgent need for alternatives to fluorinated chemicals

Part of the RELIANCE project focuses on the development of sustainable water repellency using fluor-free chemistries. This is important because fluorochemicals are notoriously persistent in nature. Nonetheless, fluorochemicals like PFOA and PFOS have been used extensively due to their excellent performance. In this context, fluorochemicals were increasingly popular in use until it became clear they were very persistent and barely degrade in nature. The use of PFOA/PFOS substances have been restricted in Europe by REACH under Annex XVII, and has recently been replaced by the Stockholm convention on persistent organic pollutants (POP) that has been in place since July 4th 2020. This novel legislation still foresees exceptions for the use of PFOA in textile applications where oil- and water repellent textiles are needed to protect employees against dangerous fluids, which include possibly pathogenic blood spat or mucosal aerosols. These applications could only make use of PFOA until July 4th 2023, indicating even the phasing out of PFOA in Europe is difficult for certain demanding applications. In most of the textile products PFOA is being replaced by perfluorohexane sulfonic acid (PFHxS) or other less harmful fluorochemicals. Under novel regulatory developments led by the German excellence BAuA, ECHA is currently investigating a further restriction also of PFHxS, as these components are also bio-accumulative. Even though exceptions for medical textiles are foreseen (25 ppb of PFHxS salts), it illustrates the difficulties in providing powerful alternatives for oil- and water repellency needed in protective clothing. The RELIANCE project is taking a radically different approach by using pretreatments with hydrogels.

Hydrogels efficiently prevent impregnation of coating pastes into the fabric

RELIANCE made use of hydrogel formation of certain polysaccharides when they are combined with salts. The main examples are alginate and pectin, that make hydrogels when combined with calcium ions and gellan gum that makes hydrogels when combined with natrium, potassium or calcium. We tried different approaches in which coatings can be applied on top of pretreated fabrics where a hydrogel formation occurs rapidly preventing the paste from further protruding in the fabric.

Next steps and optimization

In order to ensure that the coatings adhere well to the fabric, different setups have been made comparing pectin, gellan gum and alginate. Pectin proved to be unsuccessful in preventing the protrusion, but both gellan gum and alginate were very effective to achieve protective topcoatings. In a next step we tested two methods where either the hydrogel is added to the textile before coating the biobased polyurethane or whether the hydrogel forming polysaccharide could be added to the biobased polyurethane and coated on a calcium pretreated fabric. Both approaches were successful in achieving nice topcoatings, but when wash tests were performed, the first method rendered delamination of the coatings, while the second method resisted washing well.

Sustainability in protective clothing & the reliance project

Centexbel is an R&D centre for the textiles and plastics industry that has a large focus on developing sustainable methods & chemistries for textiles. For this project Centexbel works together with Alsico High tech to treat textiles with next generation antimicrobials and water-repellent chemistries suited for protective clothing. Protective clothing has an important role as it protects employees from dangerous situations (e.g. blood spat, virus particles), or it can protect production environments from human contaminations (e.g. prevent skin flakes from entering cleanrooms in electronics or production of pharmaceutical components). Alsico High Tech specializes in cleanroom clothing and has high standards in developing sustainable clothing. Alsico High Tech aims for a holistic approach for sustainable materials covering environmental, economic and social aspects of the protective clothing it develops (see Alsico’s sustainability report). But sometimes some specifications and requirements are particularly challenging. This is the case for certain classes of workwear where antimicrobial or water repellency is required. We are delighted that a consortium of companies led by Tekniker is tackling this multidisciplinary issue in the Horizon Europe project RELIANCE, where we can use the expertise of Europe’s top researchers to deal with some of the most challenging issues that our industry has to deal with.

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HADEA). Neither the European Union nor the granting authority can be held responsible for them.

© All Rights Reserved 2025 | Reliance-HE

Designed and Developed by Europroject