The goal of RELIANCE project is to design and develop smart response self-disinfectant antimicrobial nanocoatings based on a new range of antimicrobial nanoparticles. The framework, on which the actual functionalities that bring out the antimicrobial effects are being built, comprises of mesoporous silica nanoparticles (SMIN). The silica particles are obtained via modification of the well-established Stöber process, using a soft-template method. Although the process to prepare these particles is relatively simple per se, the upscale of chemical processes or reactions using larger quantities of reactants rarely goes smoothly giving comparable results to laboratory scale. The upscale of mesoporous silica nanoparticles is no exception. Furthermore, with reference to the myriad of scientific articles dealing with the silica nanoparticle synthesis, it is evident that even minute changes in some parameter may cause a significant effect on the result. Therefore, to obtain conditions that are robust enough to enable the synthesis in a reproducible manner, would be of paramount importance from the upscaling point of view.

In RELIANCE, SMIN are prepared in batch processes. Unfortunately, there is no real practical way to monitor the progress of the reaction during the synthesis itself and to do adjustments as necessary to steer the reaction into the wanted direction. Therefore, the evaluation of the outcome will be done only after the process is completed and the product isolated and purified. The method of “trial and error” is both laborious and time consuming.

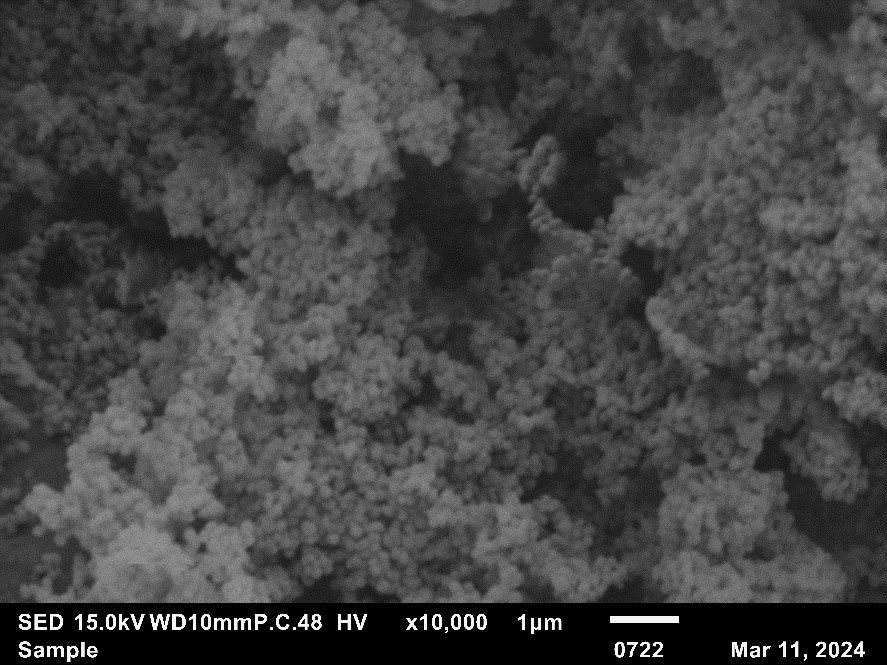

One of the key targets in RELIANCE is to produce particles with defined particle size distribution. When going to ever smaller particle sizes (i.e. nanoparticles), the task becomes more challenging. Multiple experiments have been carried out do date, to close the gap between the results obtained at lab-scale and the initial upscaled trials. The figure below shows a scanning electron microscope image of the product obtained in very recent upscaled experiment (50x reactant amounts compared to labscale). The particle size distribution measured from the image, and further supported by an independent laser diffraction analysis, are in agreement of a result very close to the targeted values. In the near future, the quest will focus on fine tuning of the current experimental parameters and set-up to still improve the particle size distribution.

When speaking about true colloidal solutions where the particles (with their size characterised in the nanometer scale, ≈ 100 nm and below) are separate and dispersed throughout the media, their isolation from the reaction mixture is not possible by simple filtration techniques and more advanced methods need to be utilised, like for example centrifugation. Preparing SMIN in quantities as set up by RELIANCE would require upscaling to volumes of tens of liters and that would no longer be viable to be processed by centrifugation. By changing the synthesis parameters, it has been observed that the formed particles start to assemble into larger aggregated structures. Formation of aggregates has a huge effect on the following step: when forming larger sized aggregates, simple vacuum or pressure filtration of the particles is again possible, therefore simplifying the work-up remarkably.

Although the aggregation is beneficial to ease the product isolation process, there is a downside. For the final coatings, particles need to be separated from each other to give well-dispersed and homogenous coating solutions. The experiments done so far demonstrate that using suitable techniques together with possible processing aids can lead to obtaining good dispersions of the particles.

Contributor: MILLIDYNE

Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HADEA). Neither the European Union nor the granting authority can be held responsible for them.

© All Rights Reserved 2022 | Reliance-HE

Designed and Developed by Europroject