On 10 February 2026, the INTEGRANO project hosted an online webinar dedicated to the Safe and Sustainable by Design (SSbD) Framework and its policy context at the EU level, bringing together 119 participants from across research, industry, and policy. The event provided timely insights into how SSbD is evolving from a policy concept into a practical driver of innovation, directly resonating with the objectives of the RELIANCE project and its work on advanced nanocoating technologies.

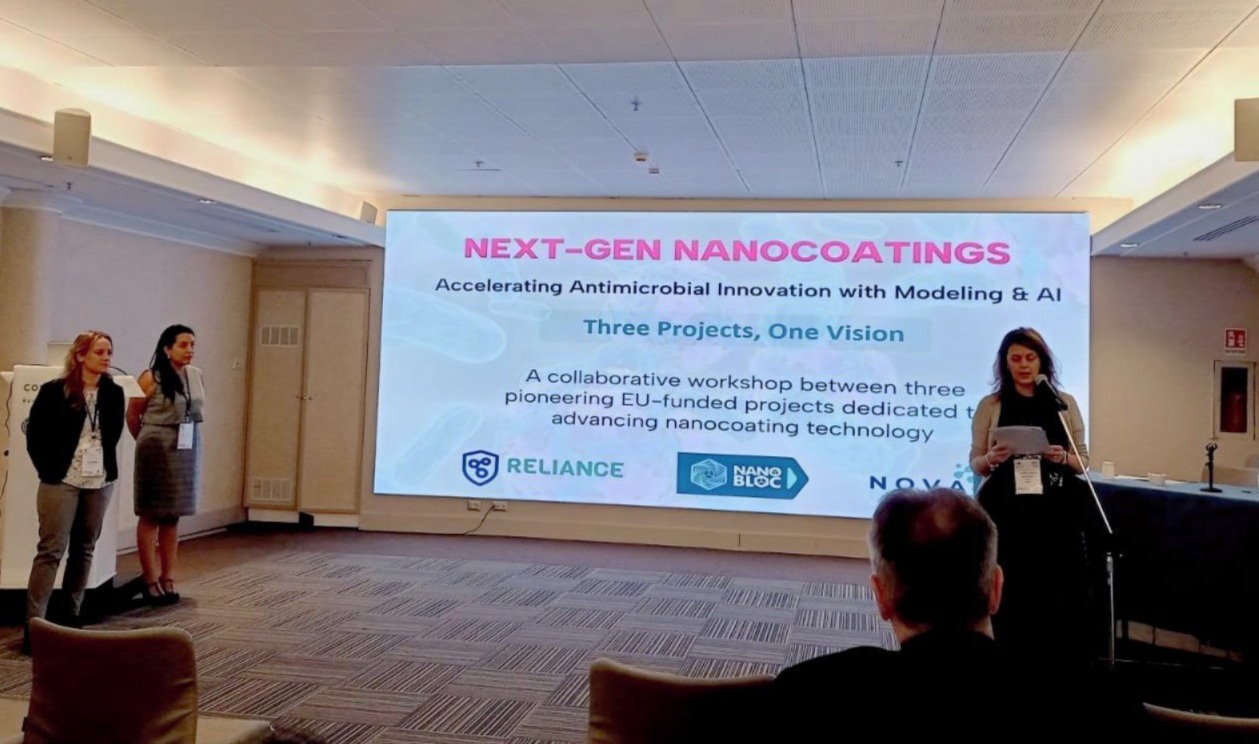

The presentations highlighted collaboration across EU-funded initiatives as essential for ensuring that safety, sustainability and performance are embedded from the very start in innovation processes, an approach that we embraced in RELIANCE too.

The SSbD Hub: Enabling Knowledge Exchange and Practical Implementation

The event also showcased the SSbD Hub, a knowledge and data exchange platform developed by INTEGRANO to support companies and innovators in the practical implementation of SSbD principles. Launched in 2024, the platform offers open access to videos, presentations, guidance documents and capacity-building activities, including online and in-person workshops.

By facilitating shared learning and harmonised understanding, the SSbD Hub strengthens the ecosystem in which innovative material science projects operate, supporting in this way the uptake of safe-by-design approaches for advanced materials, including nano-enabled solutions.

The 2025 European Commission SSbD Framework: From Concept to Practice

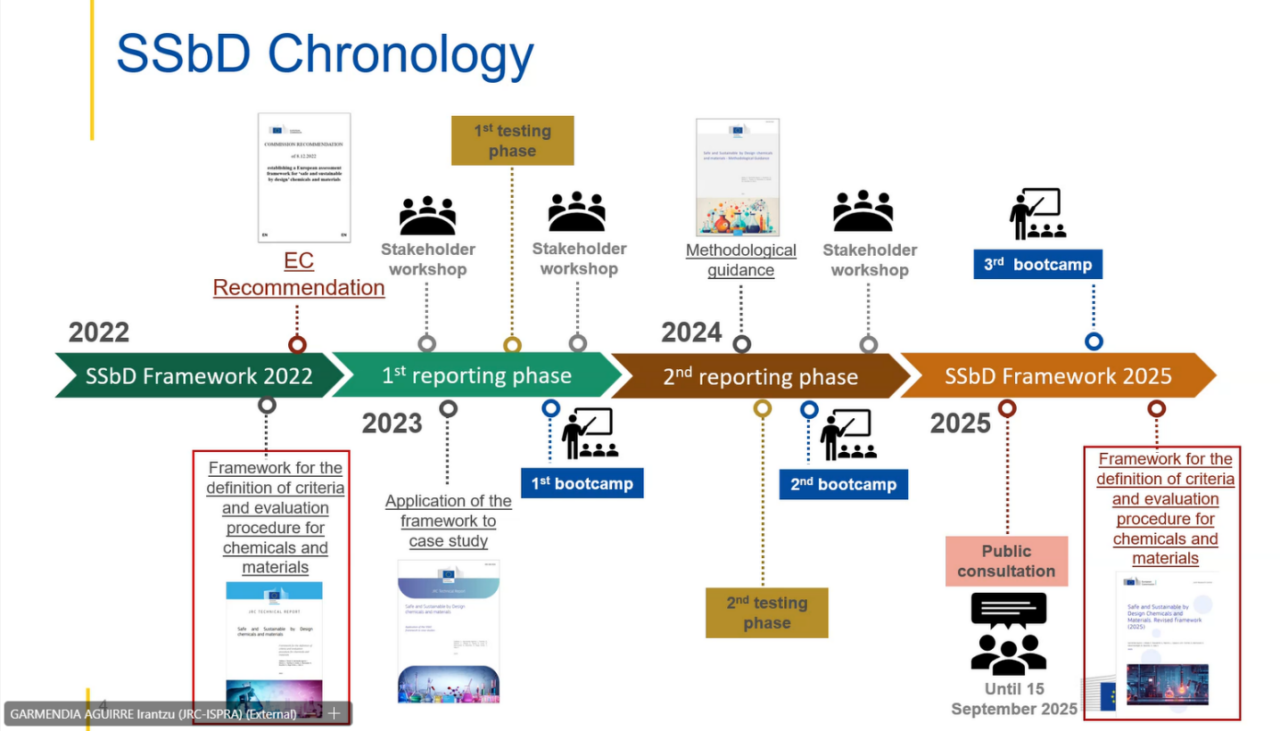

A key highlight of the webinar was the presentation of the 2025 EC Safe and Sustainable by Design Framework by Dr. Irantzu Garmendia Aguirre, Joint Research Centre. SSbD was not presented as a simple checklist but as a holistic and systematic way of thinking, integrating safety, sustainability, functionality and socio-economic considerations throughout the innovation lifecycle.

The revised framework reflects two years of testing and stakeholder feedback and moves away from a linear innovation model towards a more circular and iterative approach, better aligned with real-world R&D processes and requirements. This evolution is particularly relevant for advanced nanocoatings, where performance, durability, environmental impact and human safety must be optimised simultaneously.

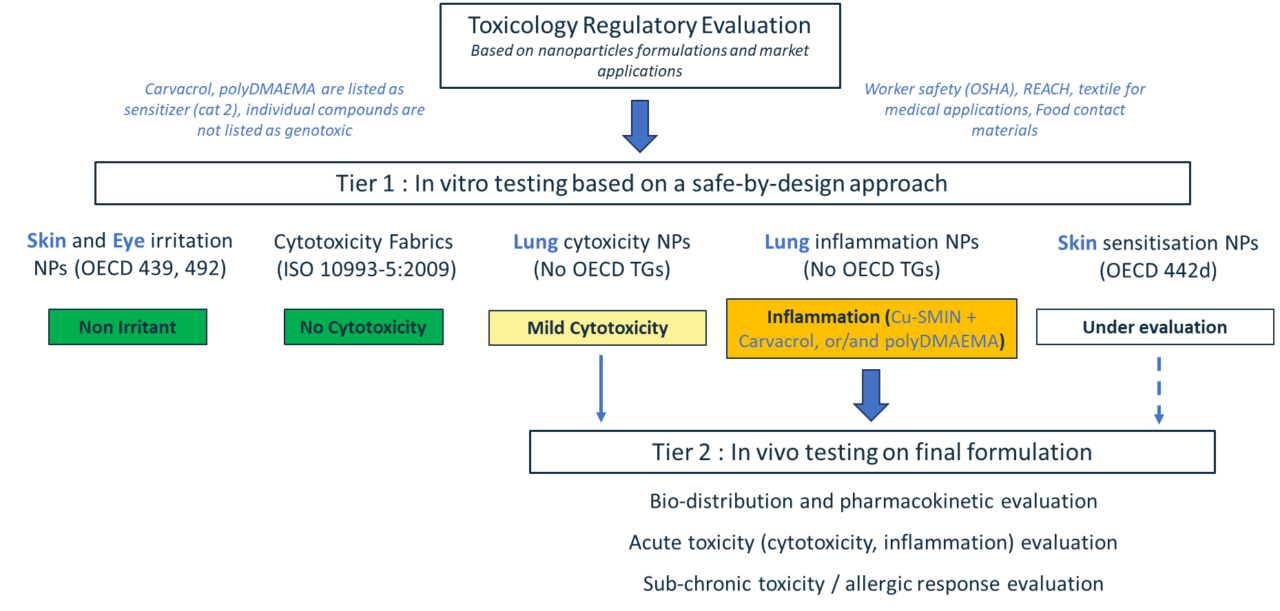

Central elements of the framework include:

- Scoping analysis – defining innovation objectives, system boundaries, lifecycle actors and redesign options.

- SSbD scenarios – enabling innovators to apply the framework at different maturity levels (Simplified, Intermediate and Full SSbD).

- Robust documentation – ensuring transparency, traceability and effective communication with regulators, investors and markets.

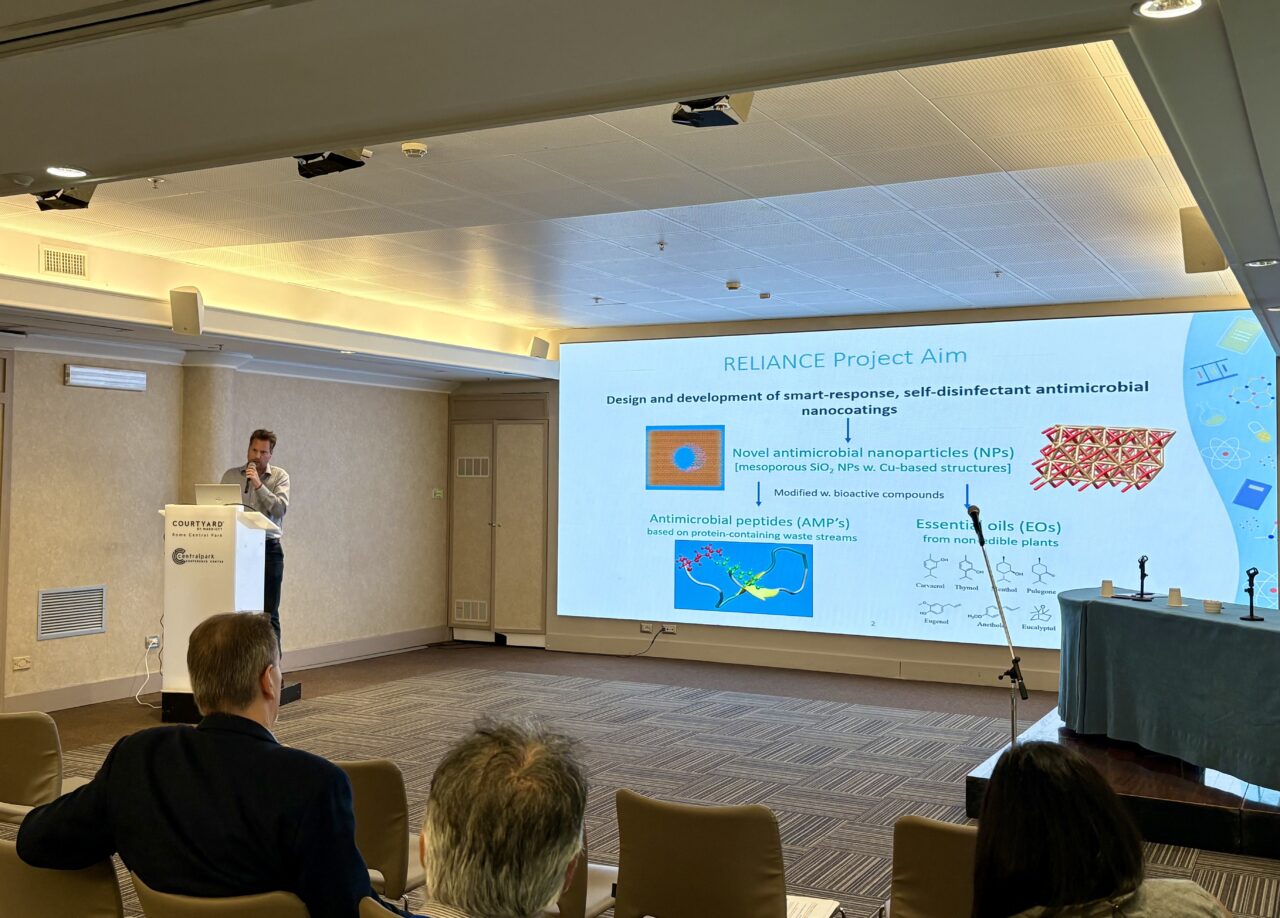

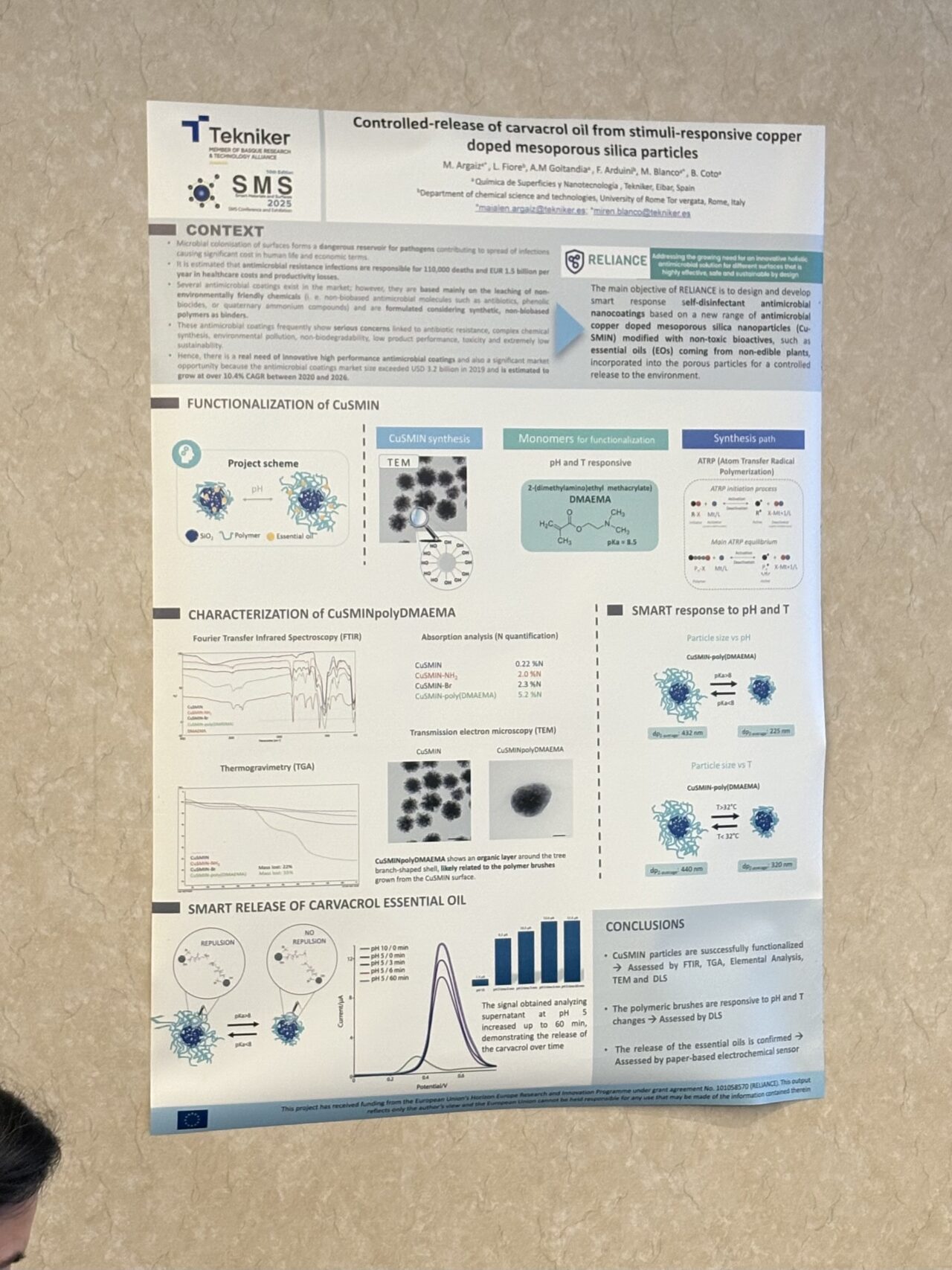

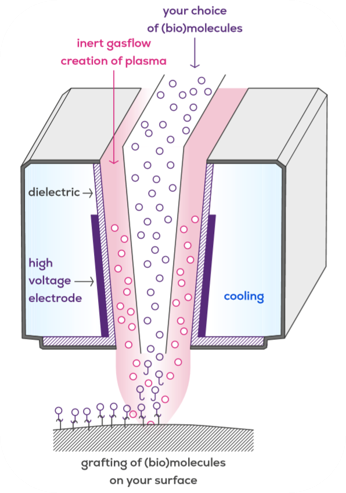

For RELIANCE, these principles were found to directly support the development of bio-based, self-disinfecting and smart response antimicrobial nanocoatings, where early design choices have long-term implications for safety, sustainability and market acceptance.

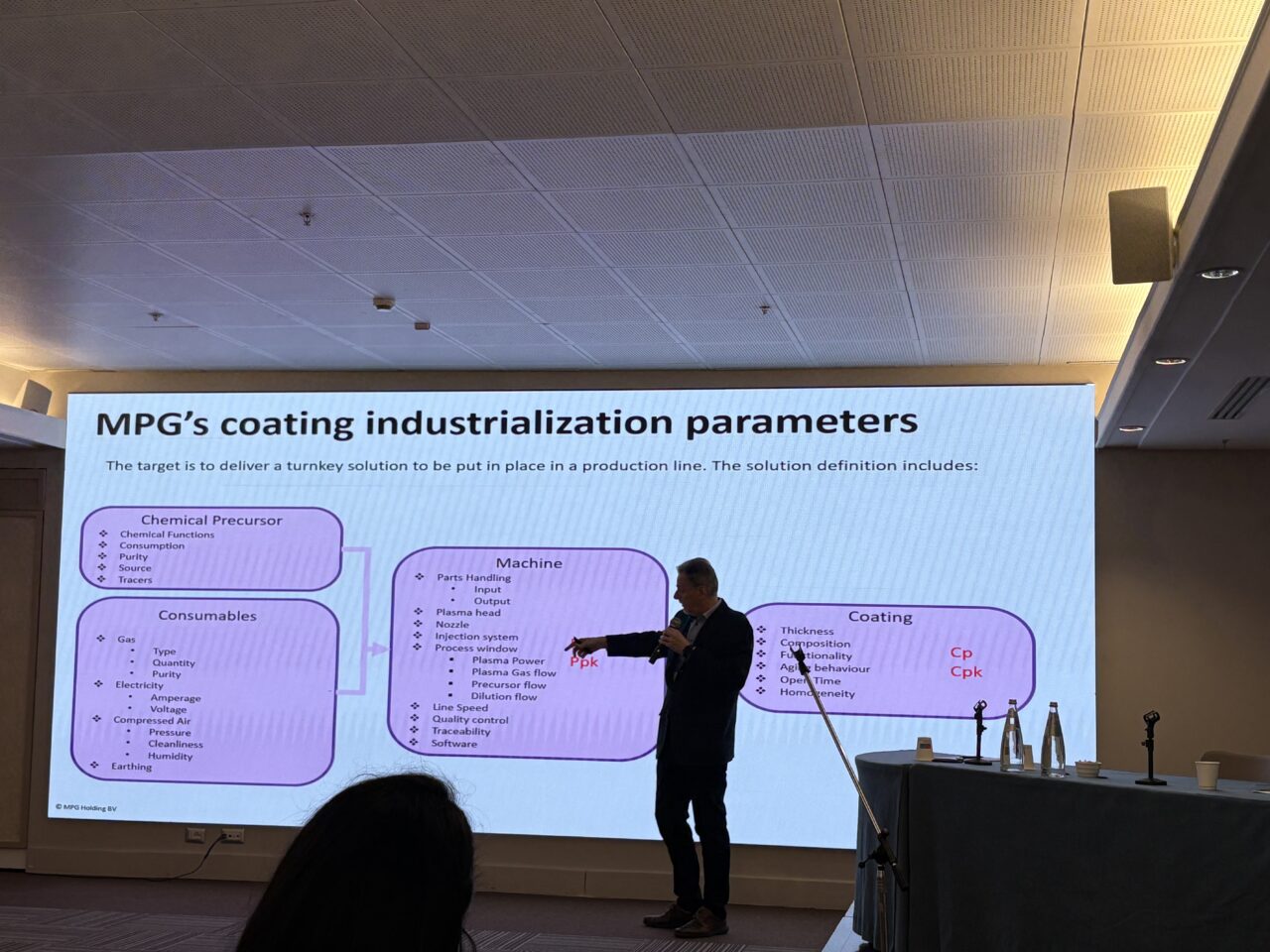

Industrial Perspective: SSbD in Practice at BASF

The webinar also brought in an industry perspective from Dr. Wibke Lölsberg, BASF SE, demonstrating how SSbD can be operationalised at scale. BASF’s Sustainable Solutions Steering (TripleS) methodology, integrates sustainability performance into business and R&D decision-making through a structured, gate-based approach.

By embedding sustainability checks at key R&D milestones and progressively increasing the depth of assessment as technologies mature, BASF’s approach illustrates how SSbD can support innovation without unneeded inhibition – a balance that is equally critical for emerging nanotechnologies developed within RELIANCE too.

The discussions during the webinar reinforced a key message: SSbD is becoming a common language across EU research, industry and policy. While currently voluntary, the framework is increasingly shaping regulatory thinking and market expectations.

For RELIANCE, aligning advanced nanocoating development with SSbD principles is not only about regulatory compliance. It is about accelerating innovation that is trusted, scalable and fit for real-world applications, from antimicrobial surfaces to sustainable industrial coatings.

By engaging with initiatives like this one, organized by INTEGRANO project, and contributing to the broader SSbD ecosystem, RELIANCE strengthens cross-project collaboration and helps ensure that next-generation nanocoatings are safe, sustainable and designed for impact from inception.

Contributor: Europroject – Tinexta Innovation Hub