As part of work package 2 activities, RELIANCE proposes the development of mesoporous inorganic nanoparticles as potential nanocontainers of bioactives, due to their high stability, biocompatibility, large specific surface area, tunable pore diameter, and easy surface functionalization. They can be obtained by sol-gel technology which offers the possibility to scale up the synthesis process due to its cost effectiveness since it does not require expensive equipment and can be applied at low processing temperatures. Additionally, the mesoporous structure of the particle allows for the possibility of adding other elements during the same manufacturing process, such as copper, which can be easily incorporated thus enabling the contact killing action of the mesoporous silica nanoparticles. The contact killing action allowed by Cu-SMIN will be combined synergistically with non-toxic biobased actives such as essential oils and antimicrobial peptides.

These particles, which have dimensions in the nanometer range, exhibit unique antimicrobial properties and once their synthesis is finalized, they can be applied in a wide range of fields, and can also be incorporated in coatings to prevent the proliferation of harmful microorganism in contact surfaces and high traffic areas.

During the first year of the project, in addition to having optimized the synthesis procedures for obtaining smart-release nanoparticles made of silica, at lab scale, we are working on the incorporation of copper and its functionalization. We are excited with these promising first results which will help our continuing fight with infections caused by bacteria, virus and fungi in the future.

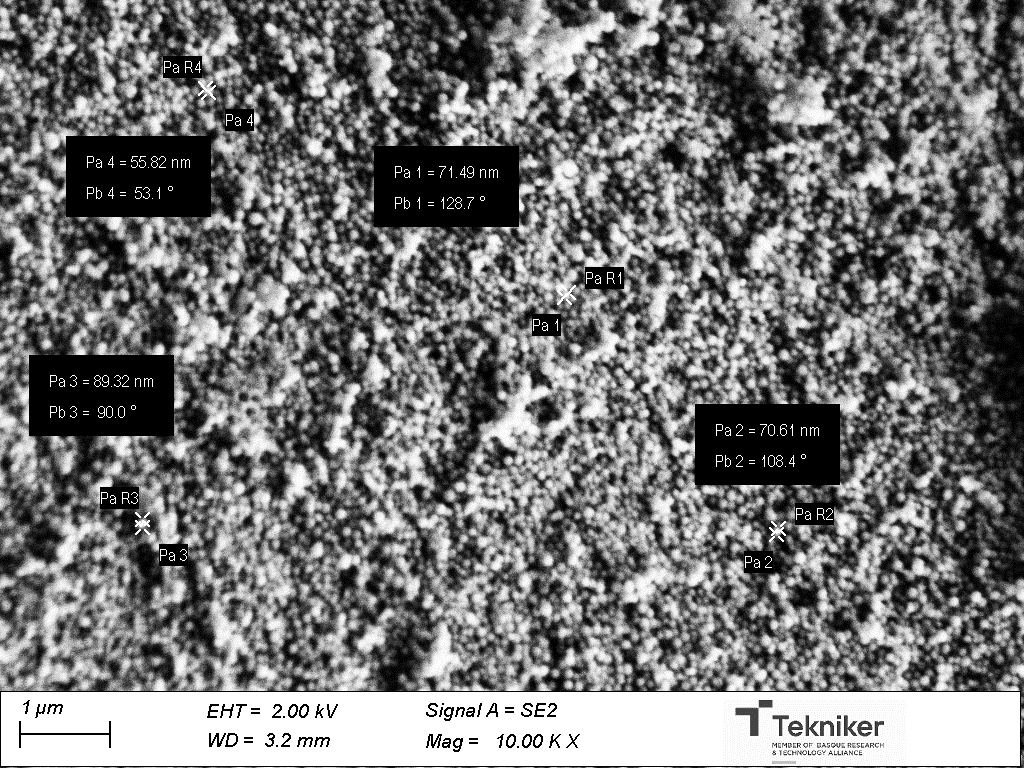

See below an image of our nanoparticles: