Essential oils have been employed for centuries in various cultures for their therapeutic properties. Beyond their delightful fragrances, essential oils are gaining increasing recognition for their potent antimicrobial activity. These volatile and concentrated extracts derived from plants possess a remarkable ability to combat a wide array of harmful microorganisms, including bacteria, viruses, fungi, and even some parasites. The exploration of essential oils as natural alternatives to synthetic antimicrobial agents has sparked significant interest in recent years, fuelled by the growing awareness of the limitations and potential risks associated with conventional antibiotics and disinfectants. Among the wide variety of essential oils available, thymol, menthol, eugenol, and carvacrol stand out for their remarkable potency in terms of antimicrobial properties. In this comprehensive exploration of essential oils for antimicrobial activity, RELIANCE is currently in progress, merging the potential of nanomaterials with essential oils to develop a highly promising antimicrobial surface. Given that one method depends on the gradual release of essential oils from loaded nanoparticles, monitoring the amount of essential oils present on the surface in real-time can serve as a valuable, fast analytical approach. In this context, it has recently been demonstrated that the paper can be used as support for the development of electrochemical devices useful for this purpose.

Paper-based sensors

Paper-based electrochemical (bio)sensors have emerged as highly attractive analytical devices for their superior sustainable features, such as avoiding the use of polyester as support and the reduction of waste, being incinerated after use. However, paper-based electrochemical (bio)sensors have recently demonstrated further advantages, including the simple combination with vertical microfluidics and their use as a reservoir to deliver smart electrochemical (bio)sensors that are able to i) contain the reagents, ii) preconcentrate the target analyte, and iii) synthesize the nanomaterials inside the paper network. Furthermore, these devices have shown ability to overcome the limitations of the other printed electrochemical sensors in the measurement of entirely liquid samples by detecting the target analyte in the aerosol phase or solid sample, without the additional sampling system. Herein, we developed in RELIANCE a paper-based device for the detection of essential oils on the surface, as a smart tool to evaluate the availability of these compounds on the functionalized surface.

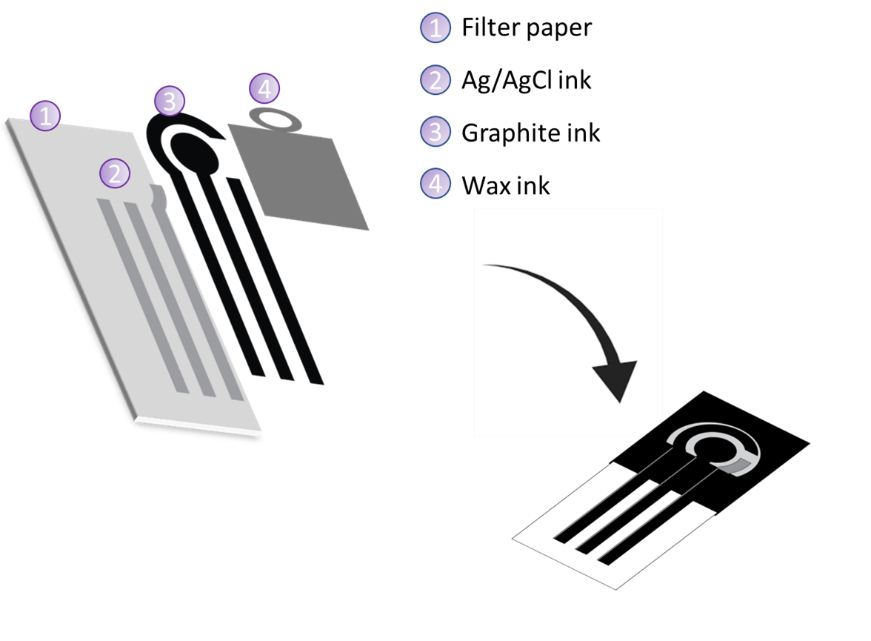

Preparation of paper-based sensor

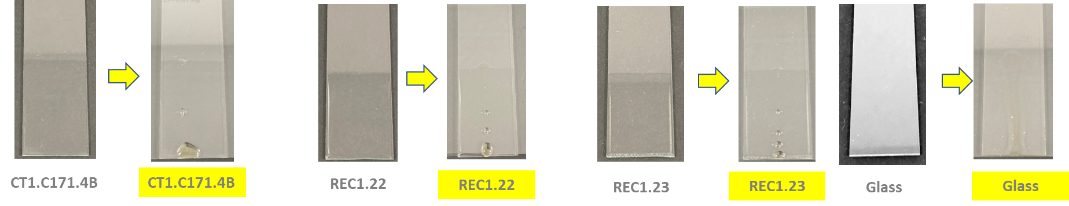

Filter paper-based screen-printed electrodes were home-produced. Filter paper sheets were firstly modified with an ad hoc designed wax pattern in order to delimitate the hydrophilic area in which liquid samples were dropped, avoiding them to reach the electrical contacts through capillary permeation. The wax pattern was printed onto filter paper by means of a special printer and treated at 100 °C for 1 min in order to allow the wax to homogeneously permeate through the paper network. Then, conductive inks were used to print a three-electrode system onto wax-modified filter paper sheets. The working and counter-electrodes were obtained using a graphite-based ink and the pseudo-reference electrode was printed using Ag/AgCl-based ink (Fig. 1).

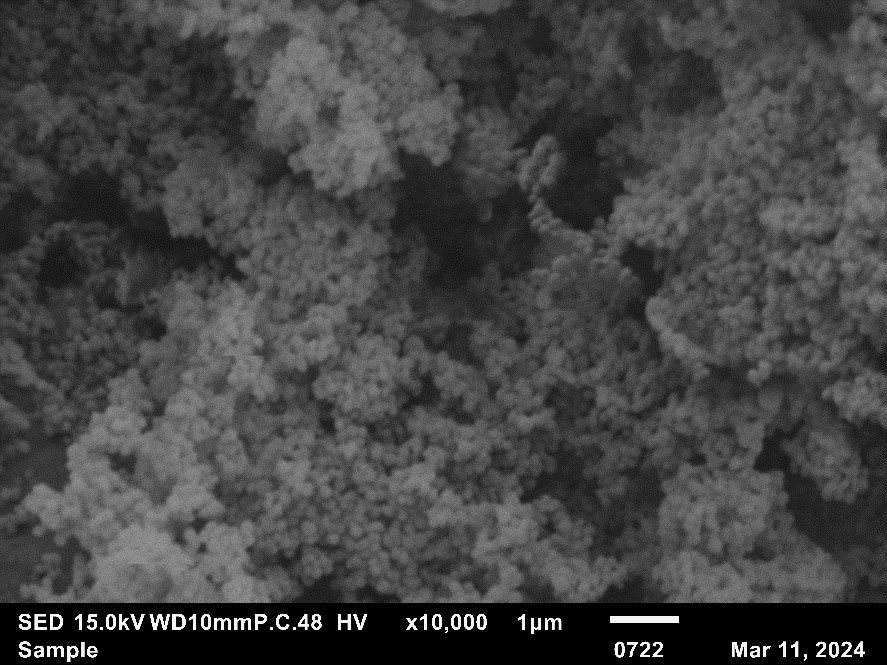

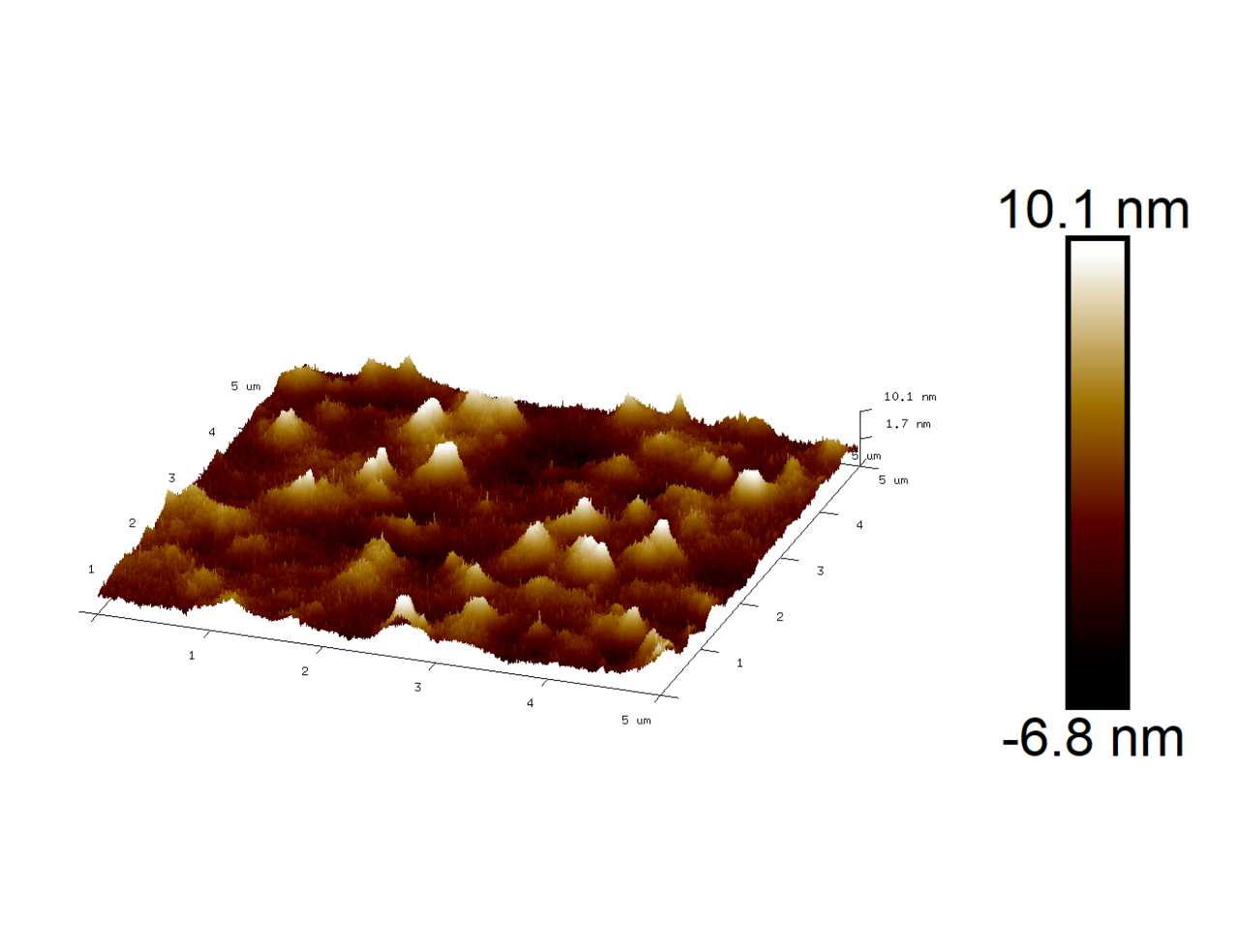

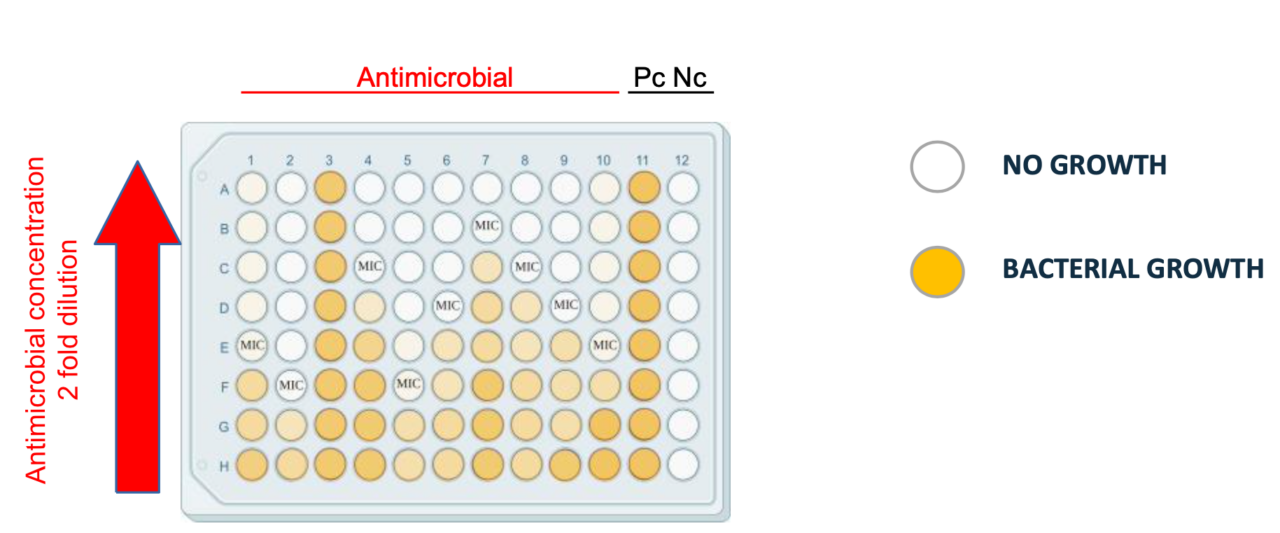

Electrochemical detection of essential oils

Different pulse voltammetry was selected for essential oils detection by connecting the paper-based sensor to a portable potentiostat connected to a laptop to easily manage the data. The modification of the working electrode surface with nanomaterial dispersion in order to improve the analytical performance of the sensor was demonstrated to be critical for the sensitive detection of essential oils. The electrochemical measurements were performed by sampling the biological compounds putting the paper strip in contact with the site wetted by oils. The calibration curves were carried out by analyzing different solutions of thymol, eugenol, and carvacrol in the concentration range comprised between 2-16 ppm.

Conclusion

The results obtained have demonstrated the ability to detect essential oils such as thymol, eugenol, and carvacrol on the surface using a paper-based device. This method offers the advantage of simplicity, sustainability and provides broad and promising applications for the detection of these substances.

Contributor: University of Rome Tor Vergata